Plants

KOCAELİ PLANTS

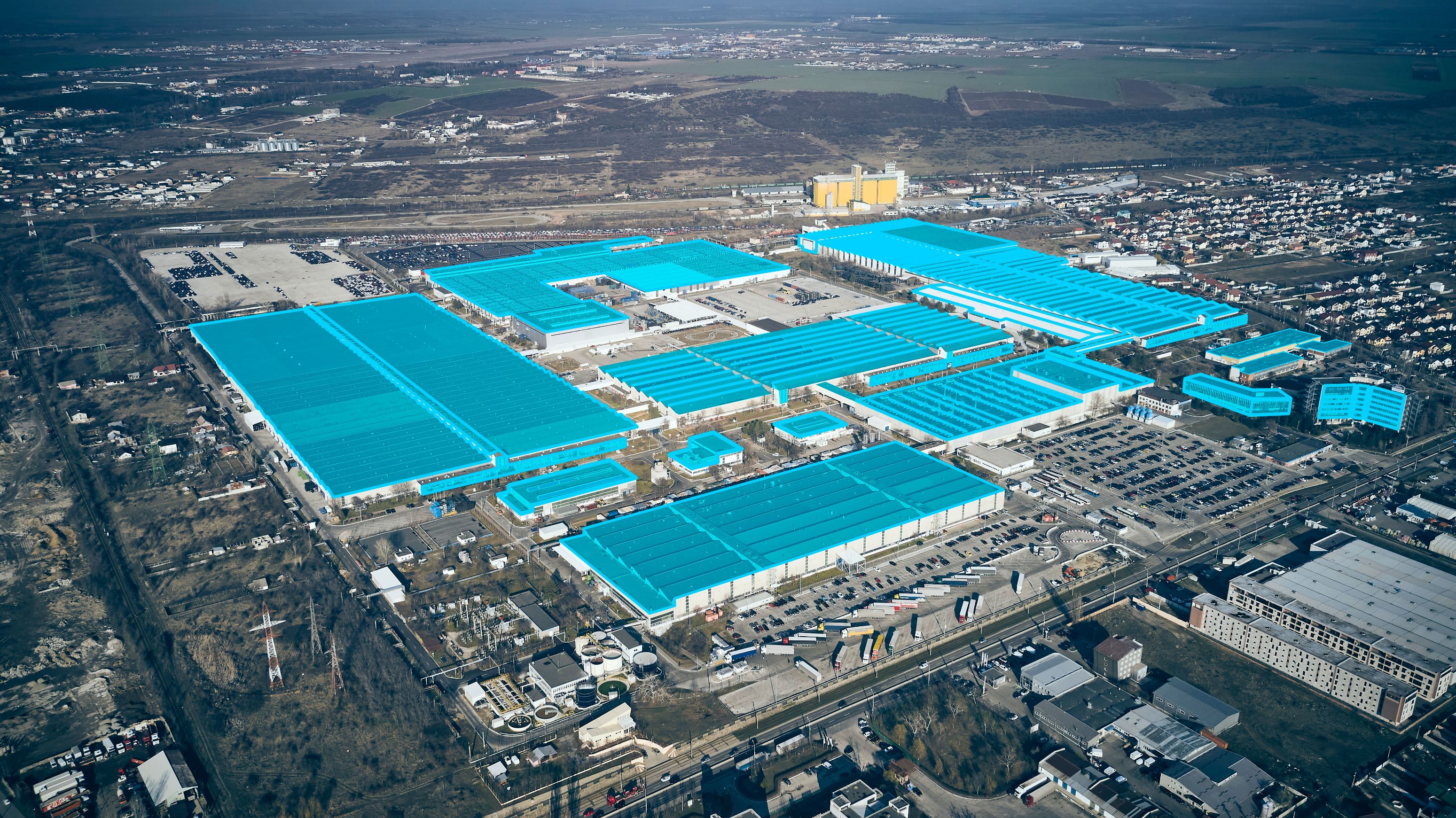

Europe’s Largest Commercial Vehicle Manifacturing Hub

Established in 2001 with an annual production capacity of 40,000 Transit units, our Kocaeli Plants have grown steadily over the years, driven by a commitment to efficient, flexible, and high-quality manufacturing. By undertaking the full production responsibility for the Transit and Custom models, our Kocaeli Plants reached a total annual production capacity of 612,000 units by the end of 2025.

The Kocaeli campus is home to the Gölcük Plant, established in 2001, and the Yeniköy Plant, which was redesigned and inaugurated in 2023.

Following the inclusion of the Gölcük Plant in the World Economic Forum’s (WEF) Global Lighthouse Network in 2019—an initiative recognizing the world’s most advanced manufacturing facilities in Industry 4.0—Ford Otosan earned further distinction in 2025 as the Yeniköy Plant was also admitted to the network.

By increasing the number of its globally recognized production facilities within the Global Lighthouse Network to two, Ford Otosan became the only manufacturing company from Türkiye to be represented with two plants on this prestigious platform.

At the same time, Ford Otosan is among the select companies worldwide with two facilities in the Global Lighthouse Network and holds the distinction of being the only production organization within Ford Motor Company to be included in the network.

GÖLCÜK PLANT - “LIGHTHOUSE FACTORY” WITH ITS INDUSTRY 4.0 FOCUSED ACTIVITIES

The Production Center of the Transit Model

Opened in 2001, the Gölcük Plant became the lead global production center for the Transit model in 2004, thanks to the high manufacturing standards of the Turkish workforce and advanced production technologies. The Gölcük Plant stands out among global Ford production facilities with its high operational standards and has received numerous domestic and international awards for its environmentally responsible manufacturing practices.

With a total area of 1,600,000 m², including 340,000 m² of indoor space, the Gölcük Plant benefits from its proximity to supplier industries and its own on-site port, providing significant logistical advantages for Ford Otosan. The facility includes Tool & Die, Press Shop, Body Shop, Paint Shop, and Assembly Operations. Central Maintenance, Production Planning, and Quality Assurance functions support the entire organization.

The first Ford Plant in the “Lighthouse Factory” network by World Economic Forum (WEF)

In 2019, following a comprehensive evaluation among 1,000 leading manufacturers worldwide, the Gölcük Plant was selected by the World Economic Forum as one of only 10 facilities across industries and regions to join the Global Lighthouse Network. As a result of our accelerated Industry 4.0 (4IR) initiatives since 2015, the Gölcük Plant became one of only four automotive factories globally to enter the network—and the first Ford plant ever to achieve this distinction.

YENİKÖY PLANT

The one and only global production center for the Custom Range

In line with its vision to lead the sustainable and technological transformation of the automotive industry, Ford Otosan inaugurated the Yeniköy Plant in 2023 following a comprehensive redesign focused on innovation and operational excellence. The Yeniköy Plant is part of Türkiye’s largest automotive investment, a €2 billion commitment announced in 2021. It sets new benchmarks in operational excellence, smart factory applications, efficiency, and sustainability.

Today, the Yeniköy Plant serves as the sole global production center for Custom models. In 2025, the plant increased its annual production capacity to 405,000 units to manufacture next-generation 1-ton vehicles. Beyond its technical excellence, the Yeniköy Plant stands out as a people-centered and inclusive facility, distinguished by its accessibility for individuals with disabilities, environmental sensitivity, strong representation of female employees, and rigorous occupational safety standards.

In 2025, the Yeniköy Plant was admitted to the World Economic Forum’s Global Lighthouse Network. Achieving this recognition just two years after rebuilding further demonstrates Ford Otosan’s globally acknowledged leadership in digital transformation.

ESKİŞEHİR PLANT

Only Plant in Turkey to bring together product diversity under one roof

We manufacture Ford Trucks (tractors, road trucks and construction series) in addition to engines and engine systems for light and heavy commercial vehicles vehicles at the Eskişehir Plant.

The Eskişehir Plant currently spreads on total indoor area of 88,000 square meters, and 1.1 million square meters of open area. The plant’s production capacity is 22,500 units of trucks and tractors for 2025.

The Duratorq and Ecoblue engines used in the Transit models, and the Ecotorq truck engines, which are developed with over $100 million in investments, compliant with the Euro 6 emission standards, and with 100% Ford Otosan-owned intellectual property rights, are produced at the plant. Eskişehir plant is the only plant in Turkey to manufacture vehicle, diesel engine and powertrains in the same facility.

CRAIOVA PLANT

Craiova plant was established in 1976 and it was purchased by Ford from the Romanian Government in March 2008. The first Ford vehicle to be produced here was the Transit Connect in 2009 Ford, followed in 2012 by Ford B-Max and the multi-award-winning 1.0 EcoBoost engine. In 2017, Craiova plant started the manufacturing of the Ford EcoSport and in 2019 the Ford Puma was launched – currently Ford’s best-selling passenger vehicle in Europe.

Established on a 1 million m² site, the Craiova Plant in Romania has an annual production capacity of 250,000 vehicles and 350,000 engines. The facility manufactures the 1.0-liter EcoBoost engine and produces the Puma model. Since October 2023, the internal combustion engine (ICE) versions of the next-generation Transit Courier and Tourneo Courier have also been produced at the Craiova Plant. As of 2025, the plant has expanded its production scope to include the fully electric versions of Puma Gen-E, E-Transit Courier, and E-Tourneo Courier, further strengthening Ford Otosan’s electrification strategy and its role in next-generation vehicle manufacturing.

Ford Otosan Craiova factory is a state-of-the-art manufacturing facility, with over 4.000 production processes, a semi-automated Stamping area, over 90% automation in Body area, including over 600 robots, a class leading 3-wet painting process including external robot paint application, 77 CNC machining centers, fully robotized cylinder head assembly and over 20 collaborative robots.

SANCAKTEPE R&D CENTER

Our Research and Development Center in Sancaktepe holds the title of being the largest R&D center in a single location in Türkiye. As of 2014, this center is the foremost R&D center in the Turkish automotive industry. On a global scale, it is also one of the largest R&D centers within the Ford organization.

Occupying an area of 35,000 m2, our Sancaktepe R&D Center includes a laboratory space of 2,300 m2. It is equipped to carry out all R&D activities from vehicle design to hitting the asphalt.

METU TEKNOKENT R&D CENTER

At our Research and Development Center located in ODTÜ Technopolis, more than 20 expert engineers are currently working.

SANCAKTEPE SPARE PARTS DISTRIBUTION CENTER

Turkey’s Largest Automotive Spare Parts Distribution Center

Ford Otosan’s Spare Parts Distribution Center, as Turkey’s largest with a warehouse spread on 35,000 square meters of indoor area, is where all of our spare parts, marketing, sales, and after sales operations are managed.

Ranking as the fourth largest among Ford’s Spare Parts Distribution Centers in Europe in terms of indoor area capacity, our center offers services to 147 dealers in Turkey and 62 dealers in 54 countries abroad. With a 97% fill rate achieved through effective spare parts management, the Center performs higher than peer Ford centers.

POLAND SPARE PARTS DISTRIBUTION CENTER

A new spare parts distribution center, spread on 1,000 m2, was opened in 2017 in Poland where storage and distribution services are outsourced. The center, which serves the Ford Trucks aftersales service centers in Europe, aims to improve lead delivery times of spare parts and increase customer satisfaction.

The spare parts distribution center in Poland offers fast delivery option for urgently needed parts with delivery guarantee within 24 hours. We export parts to 17 countries via Poland and to 54 countries in total through all of our spare parts distribution centers.